For an Austrian fruit juice manufacturer, in addition to the highest product quality, the responsible use of natural resources is paramount. An important building block for this is energy efficiency – the production should take place with the lowest possible energy consumption. The company therefore works consistently to avoid heat loss and to use previously “wasted” waste heat.

For this purpose, two Haase containers were integrated into the water supply. For this purpose, heat is extracted from the 19 ° C cold process water by a heat pump and pumped back into the cold storage at a temperature of 12 ° C. With the energy gained, the 86 ° C hot water from the return of the production process is heated by approx. 7 ° C and temporarily stored in the Haase hot water tank until it is used. The medium heated to 93 ° C is then used for several different hot water lines, for example for disinfection or cleaning processes.

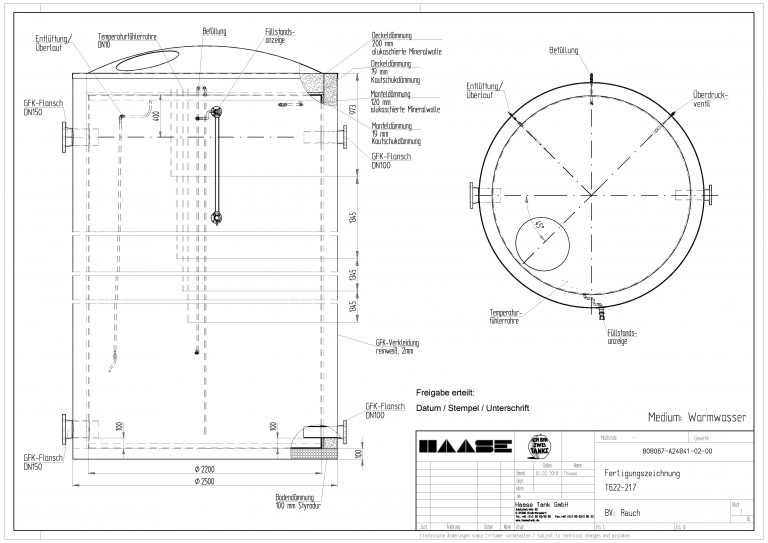

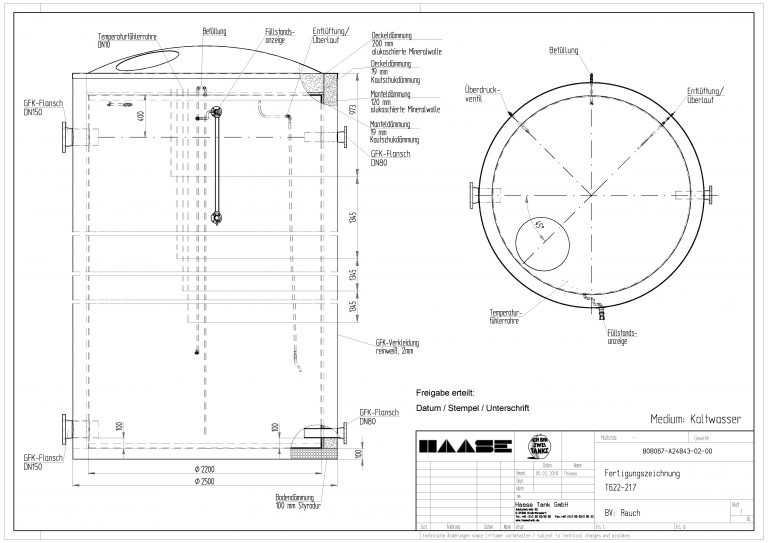

Both the cold and the hot water tank were partially prefabricated in the Großröhrsdorf factory.

With a volume of 21,700 liters each, the outer diameter of both storage tanks is 2.50 m at a height of 6.65 m.

The containers were still insulated on site and equipped with the necessary sensors.

The two Haase storage systems now help to further increase the energy efficiency of the manufacturing process.