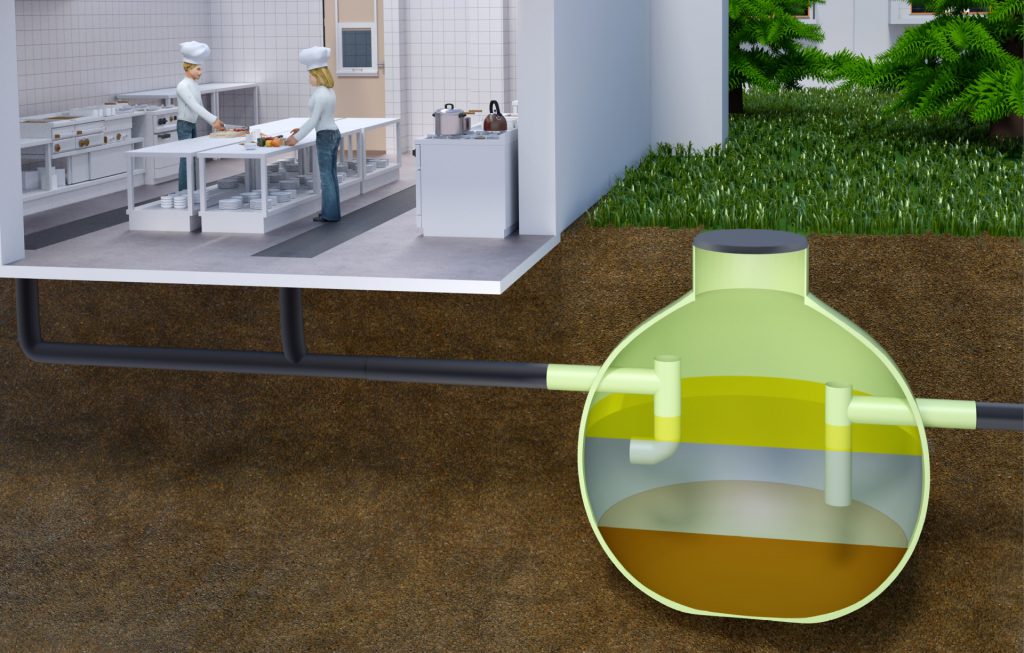

Fat Separator in the ground

Fat separators separate fats and oils from commercial wastewater and thus prevent them from entering drainage systems. In this way, they protect the sewage pipes against clogging and corrosion and ensure the proper operation of sewage treatment plants.

The Haase fat separators are characterized by their stable container. This means that the separators made of glass fiber reinforced plastic (GRP) can be installed in the drivable area without any additional reinforced concrete slabs.

THE FIELDS OF APPLICATION OF fat SEPARATORS

Grease separators are mandatory in companies where dirty and rinsing water containing grease and oil is produced.

COMMERCIAL KITCHENS

Restaurants

CANTEENS

BUTCHERS

Further areas of application: slaughterhouses, canning factories, hotels, canteens, motorway service stations, ready meals manufacturers

The advantages

of the Haase fat Separator

-

Resistance

Glass fiber reinforced plastic (GRP) as the container material is dimensionally stable and chemically permanently resistant to aggressive greases and the acids and gases generated in the separator

-

Installation

permissible up to soil class 4 (loam), with inexpensive buoyancy protection at high groundwater levels, no complex foundation required

-

Entry

uncomplicated entry through the shaft with, 1,000 mm, without annoying partition

-

Stability

Thanks to the multi-layered container structure, it can be driven under heavy loads without further concrete work; the seamless application of a dome shaft extension enables large installation depths

-

Compact

Sludge trap and grease trap are in one tank

-

Tightness

no weak points because the pipe connections and the shaft are machined to the tank in the manufacturing process

-

Weight

low weight enables short installation times and moving with an excavator, no heavy-duty crane is required

-

No follow-up costs

due to leaky joints in the shaft structure or peeling coating

-

Flexibility

the adjustable top section enables the shaft cover to be variably adapted to the top edge of the site

-

Cleaning

Due to the spherical shape, the grease separators have no edges on which dirt can adhere. Together with the smooth inner surface, this enables short disposal times and easy cleaning of the system

HOW OUR fat SEPARATORS WORK

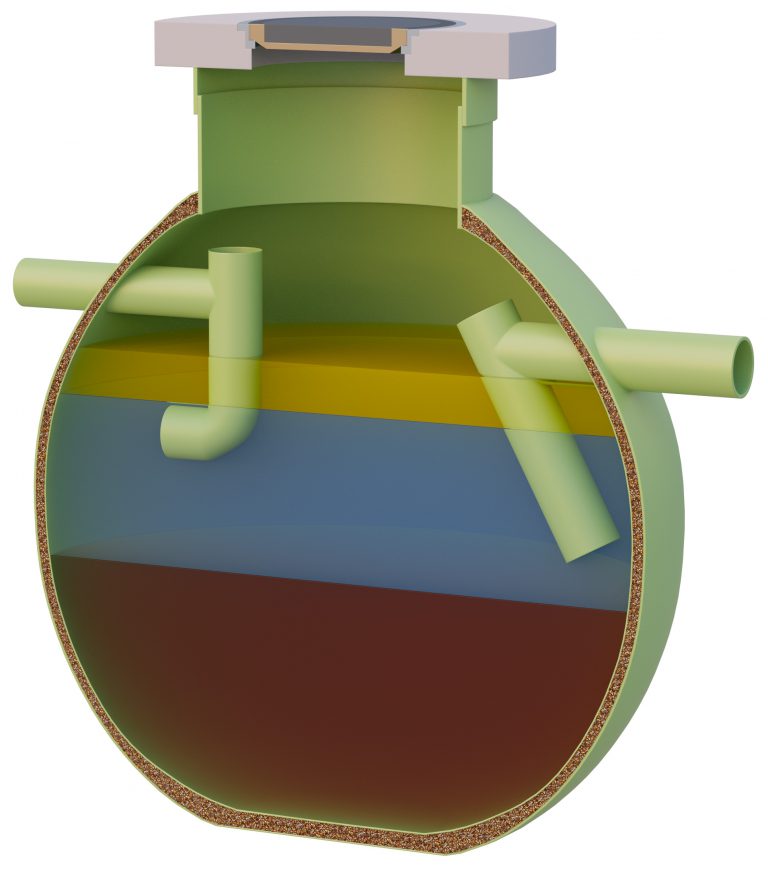

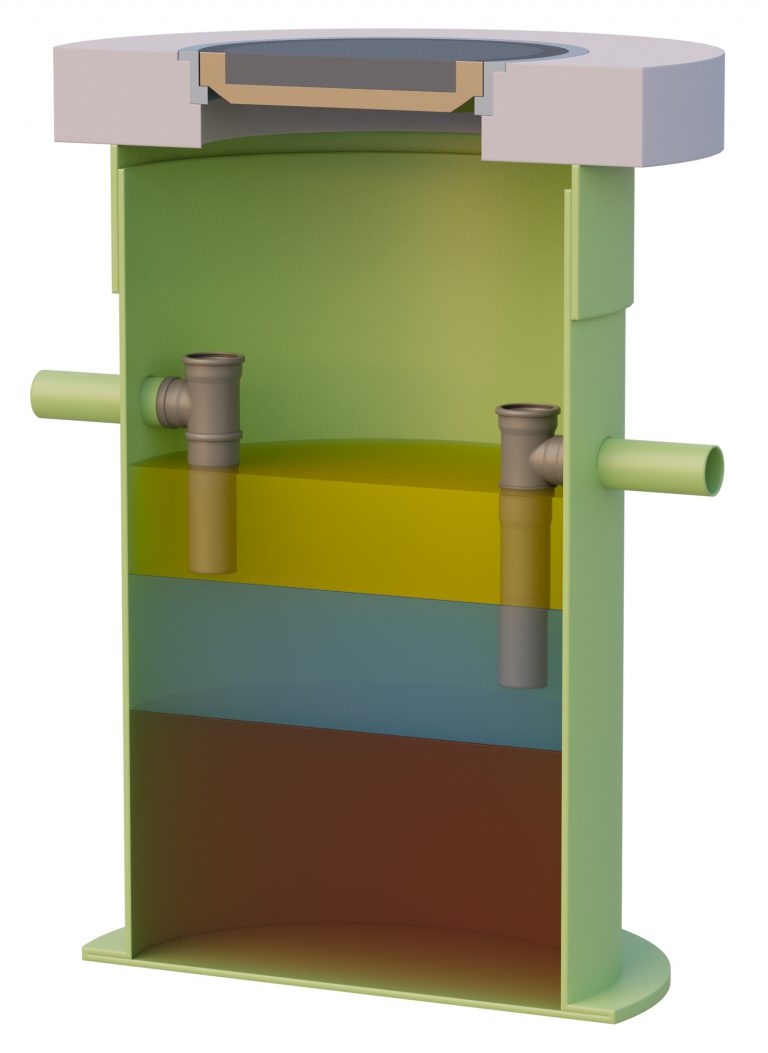

The flow rate of the incoming wastewater is reduced in the fat separator. The separation of the separable substances from the soiled dirty water takes place purely physically on the basis of the principle of gravity. Due to their lower density, oils and fats rise to the water surface and are retained in the fat separator. Due to their higher specific weight, sludge and solids sink to the bottom and are deposited there.

In the Haase separator system, the functional areas sludge trap and fat separator are arranged one above the other without spatial separation. The pre-cleaned wastewater then flows into the sewer via a sampling device. According to DIN EN 1825, the content of the separator must be completely emptied after the storage capacity of the sludge trap or fat collection space has been reached, but at least once a month. After the subsequent cleaning, the separator has to be filled again with water which corresponds to the local discharge regulations.

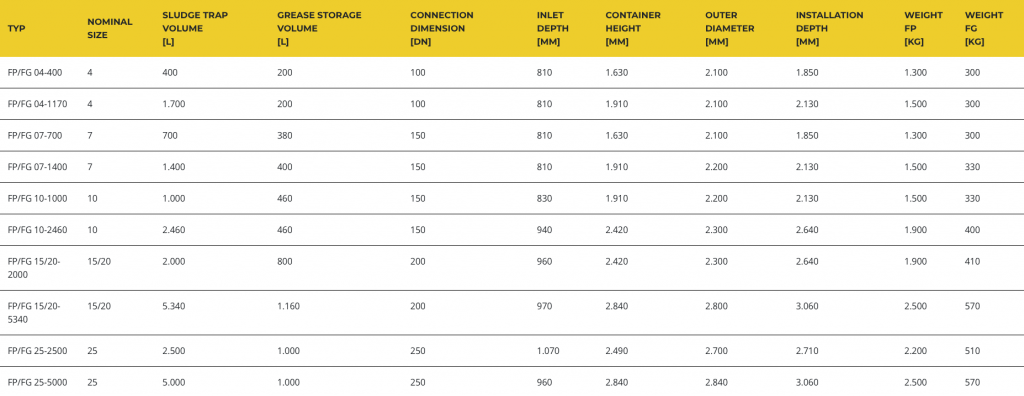

Fat SEPARATOR (FP+FG)

according to DIN EN 1825-1 and DIN 4040-100

with building inspectorate approval

Z-54.1-526 (FP = drivable variant) and

Z-54.1-540 (FG = walk-variant)

The FP separator type has a three-layer structure, and there is a filler layer made of polymer concrete between the GRP walls. This makes the fat separator highly resilient and ideally suited for installation situations in the drivable area.

The FG separator type is made entirely of glass-fiber reinforced plastic and represents a cost-effective alternative for the walk-in area.

The fat separator systems are characterized by their simple and robust technology. Both the tank and the built-in parts are made of durable plastic.

EQUIPMENT

- liquid-tight dome shaft extension

- accessible and drivable manhole cover

- alarm system for grease layer thickness

- Protective pipe connection KG DN 100, including rubber press seal

Size Cahrt

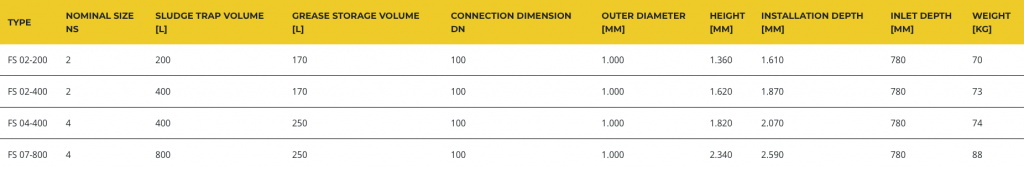

Fat Separator (FS)

according to DIN EN 1825-1 and DIN 4040-100

With type test for effectiveness and CE marking.

The FS separator type is particularly suitable for smaller companies with limited space.

Due to the slim, cylindrical container with low weight, the installation can be done quickly and cheaply.

SIZE CHART

Do you have any questions?

We will be happy to help you by phone or email.

info@haasetank.de

Fat SEPARATOR MADE OF GRP

In the field of fat separators, the material GRP really shows its strengths. It is chemically permanently resistant to animal and vegetable fats, as well as the aggressive acids that are generated in the separator. Due to the discharge of hot waste water, vapors are generated in the fat separator. This means that the shaft area and the cover must also be resistant. Haase therefore follows the consistent path and also manufactures the shaft from GRP. The drivable concrete cover is covered with GRP at the factory. So everything inside the separator is made of plastic, including the built-in parts. You can find more information on our high-quality GRP material on the following page.

THE fat SEPARATOR IN PRACTICE:

CONVINCE YOURSELF WITH OUR REFERENCES

Do you have any questions, would you like a specific offer or a free and non-binding on-site appointment? Then send us a message using our contact form or call your contact person Mr. Danilo Schlenz directly at +4935952 35515.