REDUCE COSTS WITH HEAT RECOVERY

For many commercial and industrial applications, hot water tanks from Haase offer the possibility of efficiently storing waste heat and thus saving considerable costs. The tank sizes up to 100,000 l volume, the flexibility in the equipment, the low heat loss and the corrosion resistance guarantee the high efficiency of the tank made of glass fiber reinforced plastic.

THE USE OF HOT WATER TANKS

Hot Water Tanks can be especially used where very large amounts of excess heat are produced, which can be used later. For example:

Bakeries

Laundries

Hotels

Server cooling

Other possible uses: butchers, hotels, housing estates, dairies, food manufacturers, industrial companies and much more, where waste heat is generated and can be used later.

EQuIPMENT VARIANTS OF THE HOT WATER TANK

All equipment variants listed below can be combined with each other.

This is useful, for example, if heat is constantly introduced into the storage system via a stratified charging unit and discharged again quickly via a side flange.

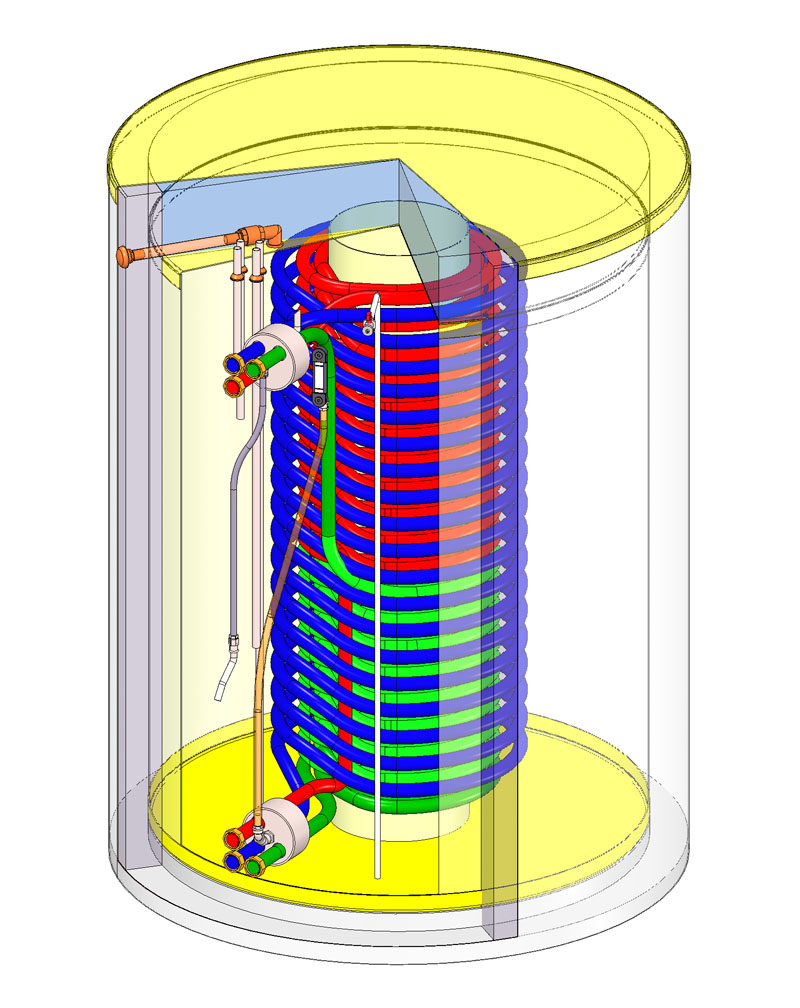

HOT WATER TANK WITH CORRUGATED STAINLESS STEEL PIPE HEAT EXCHANGERS

Functionality

Heat input and output takes place exclusively via internal heat exchangers made of corrugated stainless steel – this means that the storage medium water is completely separated from the heating, solar and drinking water circuits. The drinking water heat exchanger first removes the heat from the lower area of the tank before it is heated to the final hot water temperature in the upper area. This cooling of the lower area has the advantage that the solar system can work effectively even in the colder seasons. The heating heat exchanger is used for heating support (heat extraction for heating purposes) and post-heating (ensuring DHW heating). To ensure that the drinking water is heated, the upper area of the storage tank can be reheated.

Advantages

-

Variable equipment

With internal heat exchangers made of corrugated stainless steel pipes, direct and simultaneous storage of thermal energy from several sources is possible (e.g. solar system + solid fuel boiler + oil or gas boiler or solar system + heat pump + oil or gas boiler).

-

System separation

This prevents the tank from silting up and enables it to be designed as a pressureless tank (no expansion vessel required).

-

No legionella

Legionella cannot form due to the heating of drinking water using the flow principle.

-

Very low calcification

The geometry of the corrugated pipe causes a turbulent water flow and thus minimizes any limescale deposits.

APPLICATION EXAMPLE

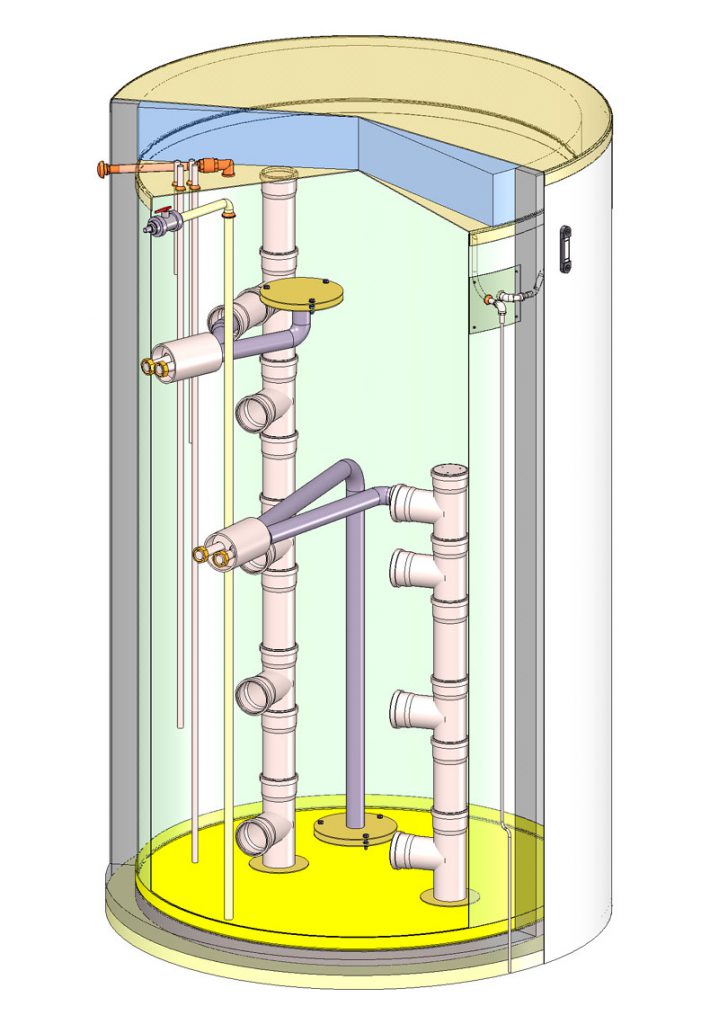

HOT WATER TANK WITH LAYER LOADING UNIT

Advantages

-

Stratification unit

In this application, systems with relatively low power can also store their energy in a large store, since the tank is layered from top to bottom.

-

Complete system separation

This prevents the tank from silting up and enables it to be designed as a pressureless tank (no expansion vessel required).

APPLICATION EXAMPLE

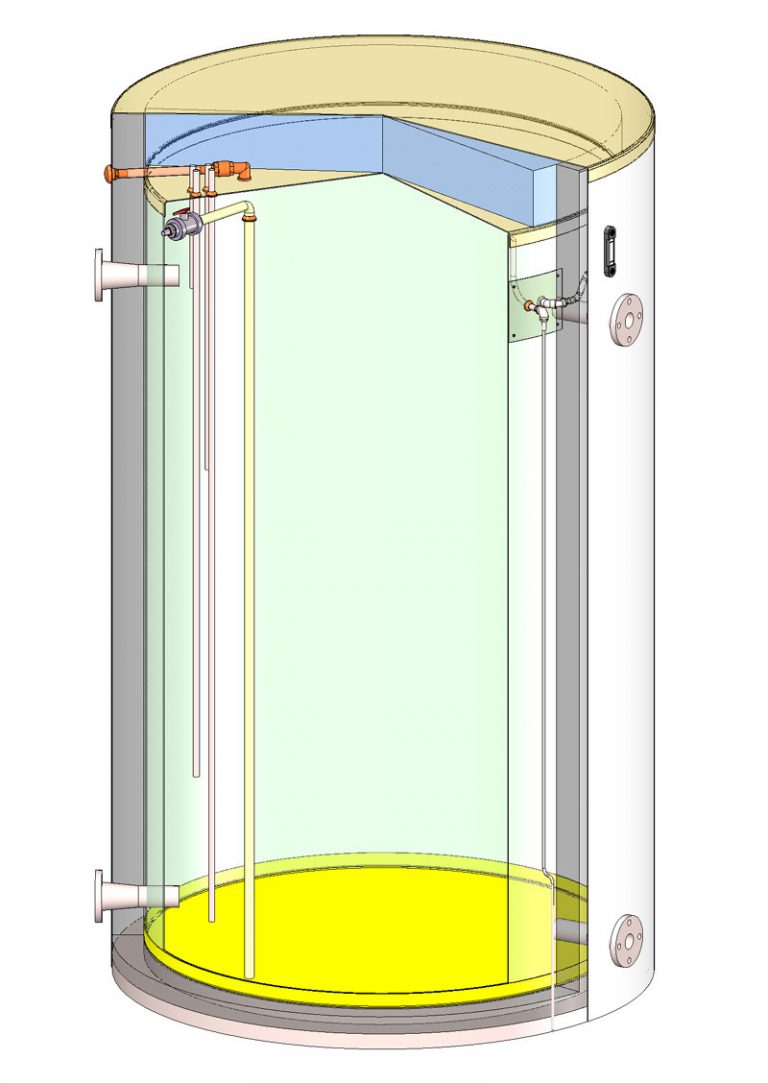

HOT WATER TANK WITH FLANGE CONNECTIONS (BUFFER STORAGE)

FUNCTIONALITY

The water is introduced or removed directly into the storage tank. During loading, the cold water is removed from the storage tank through the lower flange, heated and introduced into the storage tank through the upper flange. The buffer storage tank is discharged by removing the hot water from the upper area of the storage tank and introducing the cooled water into the lower area. Because the hot water tank is not under pressure, an external heat exchanger must be used for system separation.

Advantages

-

Any number of flanges

The buffer storage can be equipped with any number of flanges of any size – this enables it to be used as an unpressurized circuit and the storage or removal of high amounts of energy within a short time.

-

The flanges can also be arranged later

The material GRP makes it possible to attach additional flanges at a later date or to move existing ones.

APPLICATION EXAMPLE

Do you have any questions?

We will be happy to help you by phone or email.

info@haasetank.de

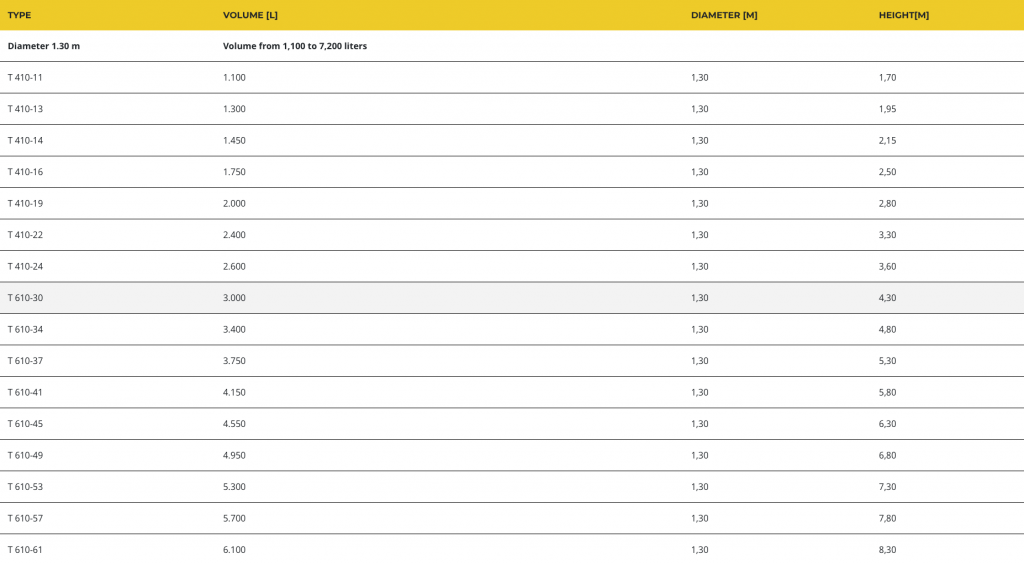

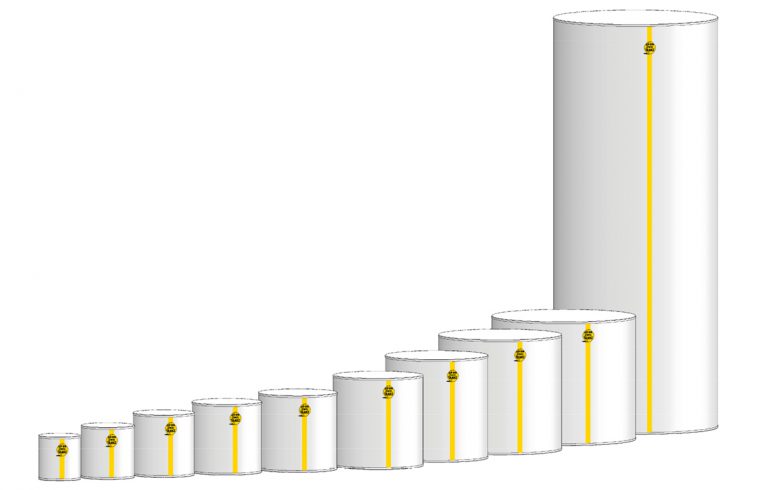

THE RIGHT SIZE FOR YOUR NEEDS

Haase offers the optimal storage size for every application: 10 different diameters between 1.30 m and 4.40 m and heights of up to 9.70 m enable a volume of up to 100,000 liters. The hot water tank from Haase can thus adapt to all spatial conditions and thus guarantees the high efficiency of the overall system.

In the case of a planned outdoor installation, assembly at the factory with subsequent transport to the construction site is also possible.

SIZE CHART

HOT WATER TANK MADE OF GRP

The material GRP has poor thermal conductivity – thus, there is only little heat loss with the Haase hot water tank. It is temperature-resistant up to 95 °C, can withstand high loads (mechanical and chemical) and is particularly long-lasting as well as resistant to aging and weather.

You can find more information on our GRP material and the various manufacturing processes on the following page.

EQUIPMENT FOR THE HOT WATER TANK

STANDARD EQUIPMENT

- Styrodur floor insulation

- Coat and cover insulation made of mineral wool

- Filling / emptying DN 15

- 4 DN 10 temperature sensor empty pipes

- level indicator

EQUIPMENT ON REQUEST

- double insulation

- Filling / emptying DN 50

- additional temperature sensor empty tubes

- Circulation lance for connecting the circulation line to the heat accumulator

- Cross flow pipe for better layer behavior of the buffer storage

THE HOT WATER TANK IN PRACTICE:

CONVINCE YOURSELF WITH OUR REFERENCES

DOWNLOADS TO THE HAASE HOT WATER TANK

Do you have any questions or would you like a specific offer? Then send us a message please using our contact form.