Large quantities of food waste and other kitchen waste accumulate in commercial kitchens, canteens, hotels, catering facilities and communal catering – this waste of food is now being fought worldwide. Modern closed disposal systems therefore offer an economically and ecologically sensible solution for the recycling of food waste, and there is also no odor nuisance in the kitchen.

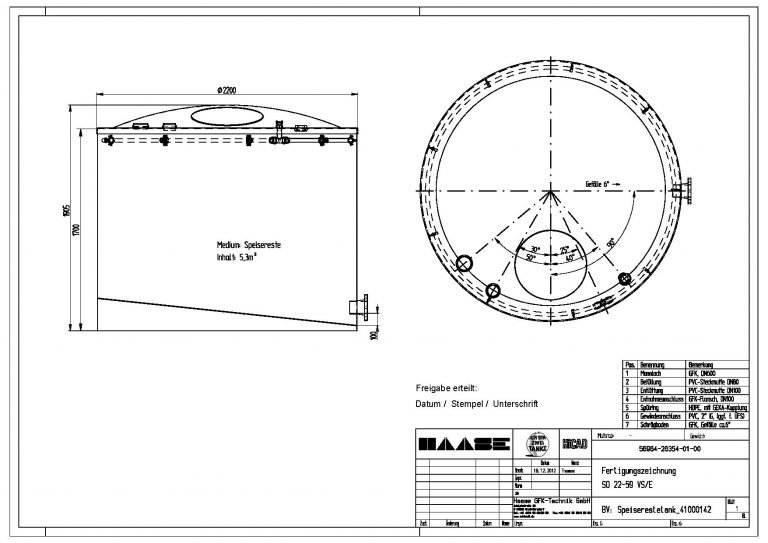

A major problem with the interim storage of organic waste is open and often too small storage containers, the handling of which is generally very uncomfortable and causes considerable hygienic problems. But how do you get a correspondingly large and permanently odor-proof tank into the installation room, whether right next to the waste recycling company or even at a further location? Doors or stairs are often an insurmountable obstacle for factory-made tanks.

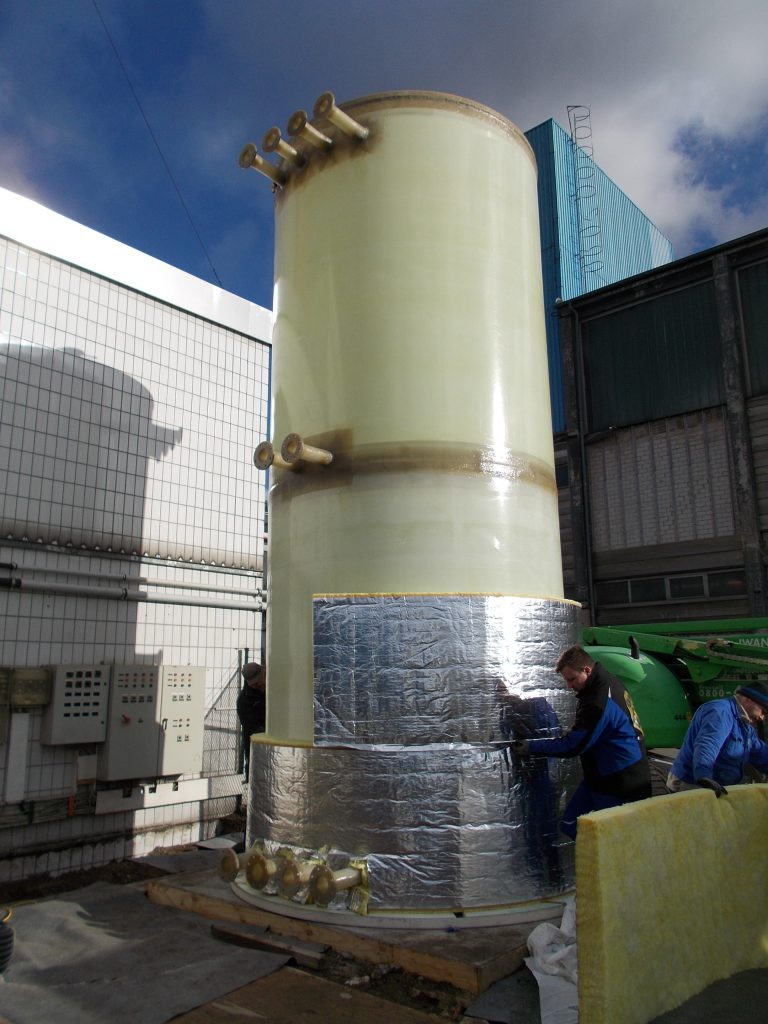

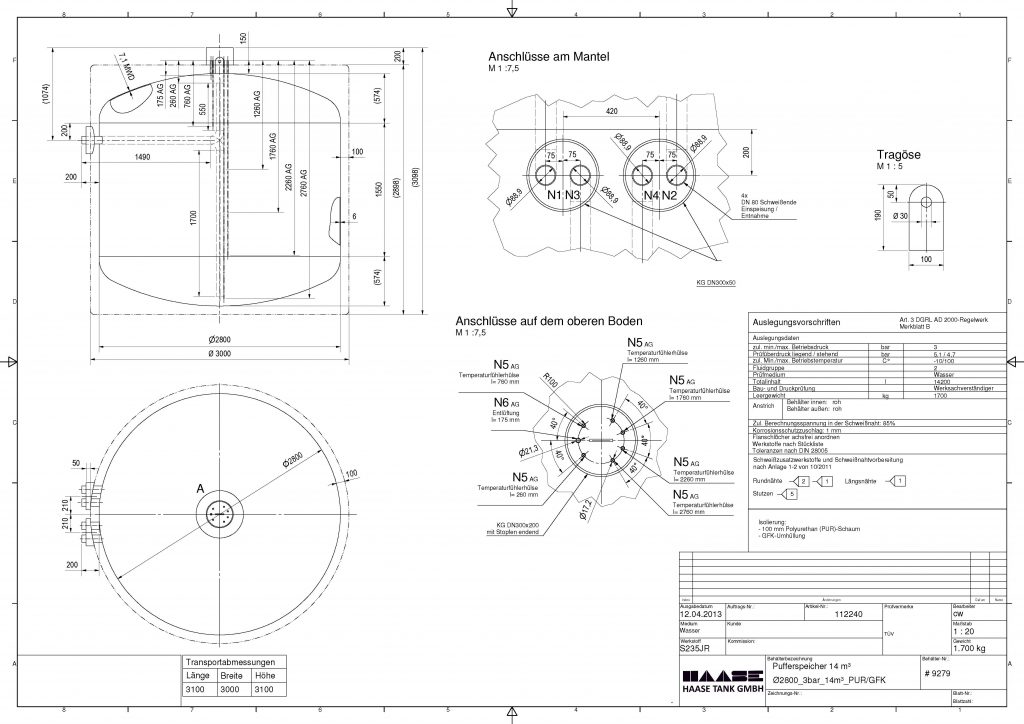

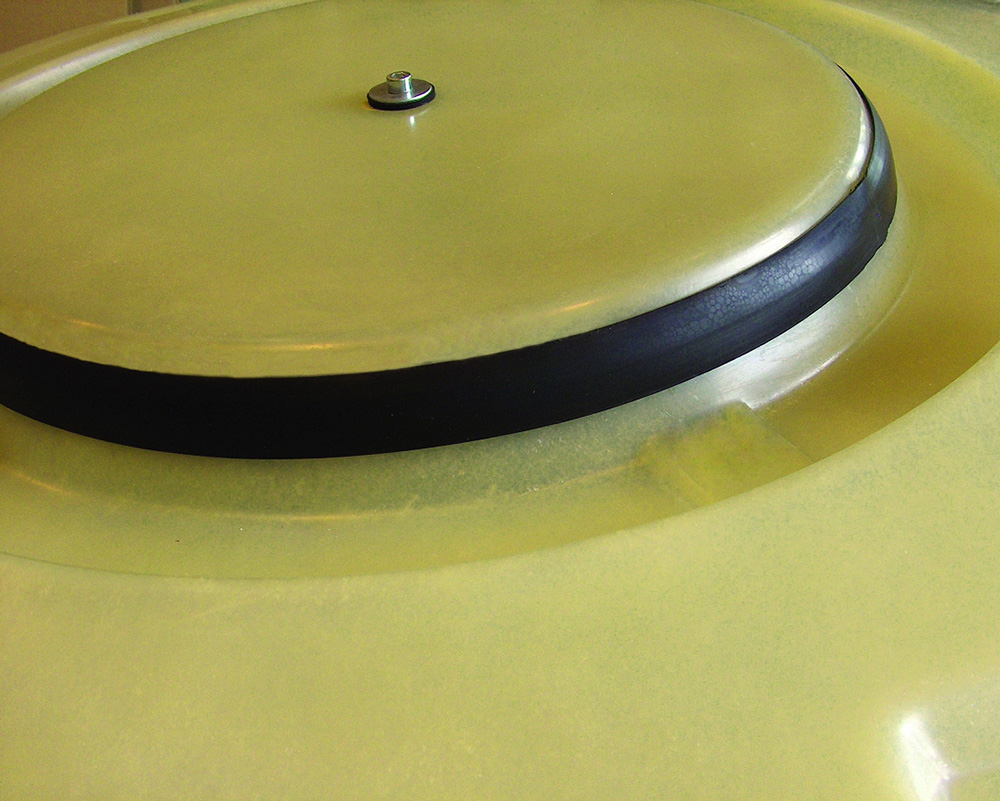

Haase offers a convincing solution with its on-site flat-bottom tanks: The tank is delivered in parts and only assembled in the installation room. Even large containers with a volume of over 35,000 liters only need a passage width of less than 1 meter.